Introduction

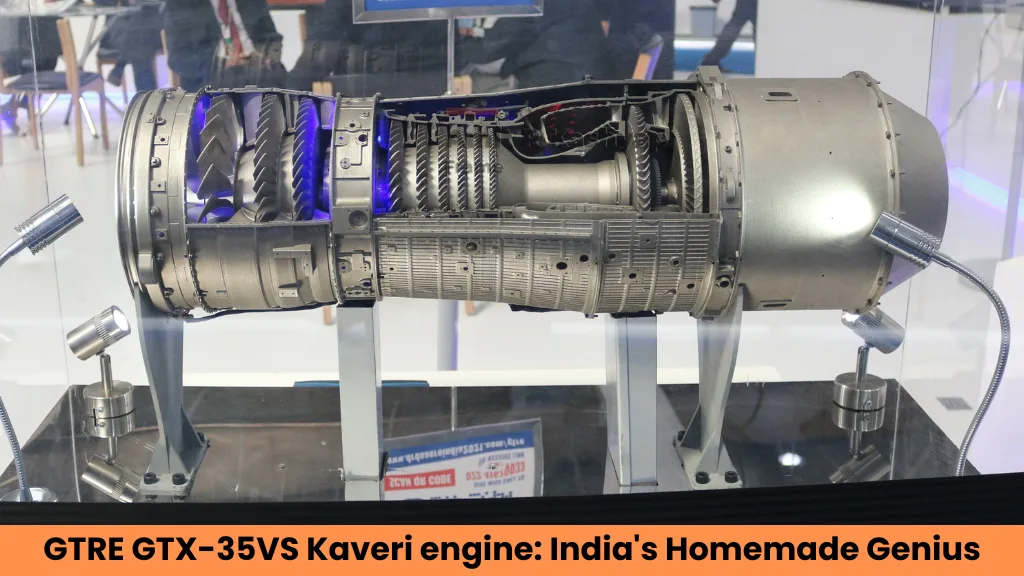

The GTRE GTX-35VS Kaveri Engine is an indigenous afterburning turbofan, developed by the Gas Turbine Research Establishment (GTRE), a unit under India’s Defence Research and Development Organisation (DRDO).

Designed to power the HAL Tejas Light Combat Aircraft (LCA) and other future aerospace applications, the Kaveri engine is a prime example of India’s growing capabilities in advanced aerospace technology.

In this article, we explore the latest June 2025 updates on the GTRE GTX-35VS Kaveri Engine, including its specifications, performance metrics, key challenges, historical evolution, and its potential to revolutionise India’s future in jet propulsion technology.

Historical Context and Development Timeline

Initiation of the Kaveri Program

The Kaveri engine project was first authorized in 1986, following the Indian Defence Ministry’s decision to develop a domestic powerplant for the Tejas LCA. Although the initial LCA prototypes were powered by the General Electric F404-GE-F2J3 afterburning turbofan engine, the goal was always to transition to an indigenous engine. This move would not only enhance India’s self-reliance in military aviation but also set the stage for advancements in indigenous aerospace technology.

Development Timeline Overview

1990s:

- 1986: The Kaveri engine project was officially initiated.

- Plans were put in place to build 17 prototype engines.

- The first test engine, the “Kabini” core module, successfully ran in March 1995.

- Ground-test engine operations began in 1996, with all five engines being operational by 1998.

- Although initial flight tests were slated for 1999, progress was hindered due to political and technical challenges, including sanctions imposed following India’s 1998 Pokhran nuclear tests.

2000s:

- 2002: Kaveri faced turbine blade failures, which led to parts being sourced from Snecma, a French company.

- By 2003, the project faced more delays and, as a result, the decision was made to procure the F404-GE-IN20 engines for the pre-production LCA aircraft.

- By December 2004, over ₹13 billion had already been spent on the project, with the cost estimates rising to ₹28.39 billion.

- 2005: There was a report on progress, with plans to integrate the Kaveri engine into the LCA prototypes by 2007.

- 2006: PRAT&T, a company based in France, expressed interest in collaborating with DRDO, but DRDO insisted on keeping the project indigenous.

- 2007: The GTRE decided to divide the Kaveri program into two streams: K9+ (development) and K10 (a joint venture with foreign partners).

- 2008: A modified version of the Kaveri engine was announced for naval applications. By September 2008, it was clear that Kaveri wouldn’t meet the requirements for the Tejas, leading to continued reliance on foreign engines.

- 2009: Reports indicated that ₹20 billion had been spent, but Kaveri had still not met the required thrust specifications.

2010s:

- By May 2010, a cumulative 1,880 hours of testing had been completed on Kaveri prototypes.

- In June 2010, there was a consideration to base the Kaveri engine development on the Snecma M88-2 engine, furthering international collaboration.

- November 2010 marked a milestone, as the Kaveri engine was tested aboard an Il-76 aircraft.

- By 2011, setbacks with the engine’s weight and delays in crucial system developments emerged.

- 2012: The lack of foreign assistance continued to hinder progress, but efforts were still in place to have Kaveri ready for the Tejas by year-end.

- In 2013, GTRE sought new overseas partners after co-development stalled with Snecma.

- 2014: DRDO announced plans to abandon the Kaveri program due to ongoing deficiencies.

- In 2016, France proposed a €1 billion investment to revitalize Kaveri, offering partnership opportunities.

- By November 2016, DRDO and Snecma confirmed a collaborative effort to rejuvenate Kaveri for the Tejas.

2018: Despite some faltering in collaboration and accusations of minimal technology transfer, Kaveri was deemed ready for restricted integration into the Tejas.

Recent Breakthroughs

By 2024, significant advancements had been made, including the development of Near Isothermal Forging Technology for high-pressure compressor discs, as well as casting technology for turbine blades. These improvements are essential in enhancing Kaveri’s overall performance.

Current Status

Today, the Kaveri engine has reached higher Technology Readiness Levels (TRLs). However, it still cannot meet the thrust demands required for the Tejas FOC variants.

Looking ahead, a proposal for the joint development of a new engine, based on Kaveri’s insights, is being discussed for the HAL AMCA (Advanced Medium Combat Aircraft).

GTRE GTX-35VS Kaveri Engine Specifications

The GTRE GTX-35VS Kaveri Engine is designed to meet the demanding performance requirements of modern combat aircraft. Below are its key specifications:

| Specification | Detail |

|---|---|

| Engine Type | Afterburning turbofan |

| Length | 349.0 cm (137.4 in) |

| Diameter | 90.9 cm (35.8 in) |

| Dry Weight | 1,180 kg (2,601 lb) |

| Military Thrust | 52 kN (11,700 lbf) |

| Afterburner Thrust | 81 kN (18,100 lbf) |

| Specific Fuel Consumption | 0.78 lb/(lbf·h) (79.52 kg/(kN·h)) |

| Overall Pressure Ratio | 21.5:1 |

| Airflow | 78 kg/s (172 lb/s) |

| Bypass Ratio | 0.16:1 |

| Turbine Entry Temperature | 2,600 °F (1,427 °C; 1,700 K) |

Kaveri Engine Performance Metrics

The Kaveri Engine is designed to meet strict military performance standards:

- Performance: With a military thrust of 52 kN and afterburner thrust reaching 81 kN, the Kaveri engine provides rapid acceleration, which is crucial in combat scenarios. Its high thrust-to-weight ratio allows for exceptional agility in aerial engagements.

- Benchmarks: The engine has undergone rigorous testing, achieving significant benchmarks that demonstrate its robustness and reliability.

Overcoming Challenges of GTRE GTX-35VS

The Kaveri project has faced numerous challenges that have tested GTRE’s abilities:

- Technical Challenges: The early failures of turbine blades required parts to be sourced from foreign suppliers, highlighting a significant hurdle in achieving self-sufficiency.

- Political Challenges: Political sanctions, particularly following India’s 1998 nuclear tests, delayed development and required adaptation to changing circumstances.

GTRE: Recent Developments and Technological Advancements

Despite its difficult history, recent developments have provided promising results for the Kaveri engine. As of 2024, the focus has shifted to producing variants of the Kaveri suitable for newer applications, such as unmanned aerial vehicles like the DRDO Ghatak.

- Power Efficiency: There is ongoing work to improve the engine’s power efficiency, ensuring it performs effectively in various operational conditions while maintaining fuel economy—an essential factor for prolonged military operations.

Kaveri Engine in Comparison to Intel Processors

Drawing a comparison between the Kaveri engine and computing platforms provides a fascinating insight into cross-domain design principles.

- Kaveri vs Intel Processors: AMD’s Kaveri APUs integrate CPU and GPU technologies, just as the Kaveri engine balances thrust and efficiency. This cross-domain comparison highlights the similarities in how technology can be optimized for different uses.

- Kaveri APU: The AMD Kaveri APU integrates CPU and GPU capabilities to enhance energy efficiency and performance. This dynamic approach mirrors the Kaveri engine’s emphasis on balancing performance metrics, providing insights into both fields’ technological advancements.

Kaveri Engine Gaming Performance

Although the Kaveri engine is not designed for gaming, its APU counterpart demonstrates strong graphics processing performance.

- Gaming Performance: The APU’s gaming performance showcases AMD’s ability to deliver enhanced graphical capabilities. This could inspire similar innovations for Kaveri, focusing on improving its operational capabilities.

Conclusion

The GTRE GTX-35VS Kaveri Engine stands as a monumental effort in India’s quest for self-reliance in aerospace technology. Despite numerous challenges, the Kaveri engine reflects India’s resilience and commitment to advancing its aerospace capabilities.

The lessons learned from this project not only apply to military applications but also have the potential to influence consumer technologies, further solidifying India’s position in the global aerospace landscape.

As the Kaveri engine continues to evolve, its future applications could extend well beyond military aviation, marking a significant chapter in India’s journey towards technological excellence.

Through persistence and innovation, the Kaveri project exemplifies the spirit of self-sufficiency and ambition to achieve cutting-edge aerospace advancements.

Learn more at DefenceNewsIndia.in – your trusted source for updates on India’s defense, aerospace, and strategic innovations.